Defining a Single Angle Connection

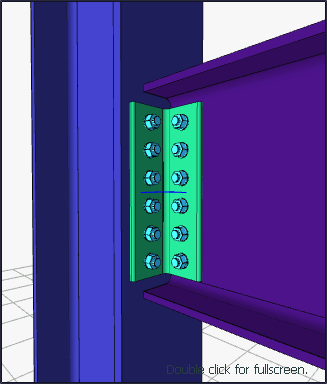

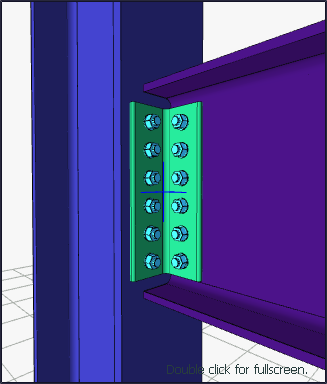

With the Single Angle Connection command, column-beam connection is defined.

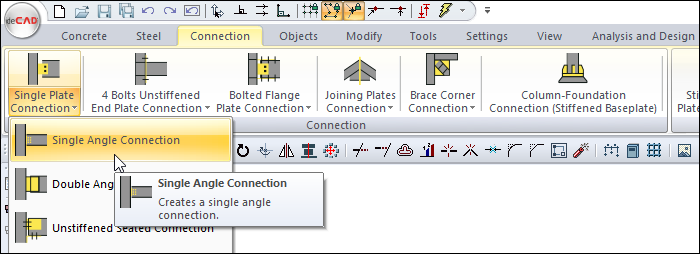

Location of the Single Angle Connection Command

You can access it under the Ribbon menu, Connection tab, Connection title.

Usage Steps

If Draw in Fast Mode is Active

From the connection menu, click the Single Angle Connection icon.

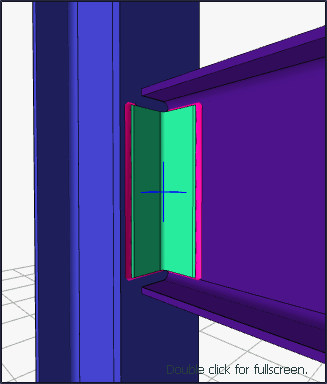

In 3D perspective view, move the mouse pointer closer to the element, close to the support

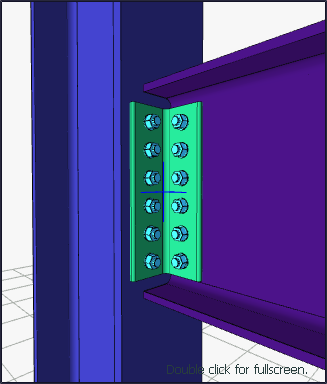

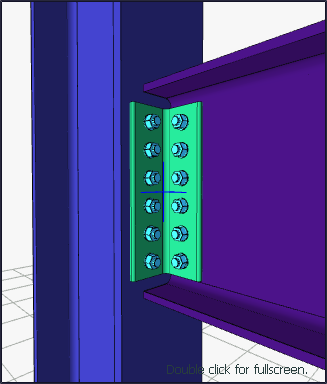

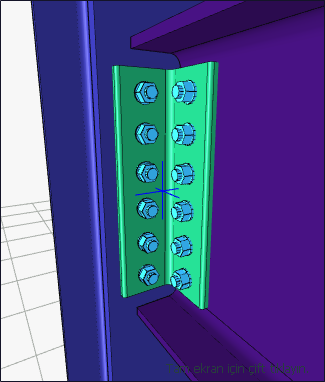

After this process, the virtual image of the connection will appear.

If the connection is suitable, create the connection by clicking the left mouse button.

The connection will occur with default settings.

If Draw in Fast Mode is Inactive

From the connection menu, click the Single Angle Connection icon.

Click the column then the beam before the 3D perspective view.

The single angle connection settings dialog will open.

The connection will occur when the wanted settings are made and the OK button is clicked.

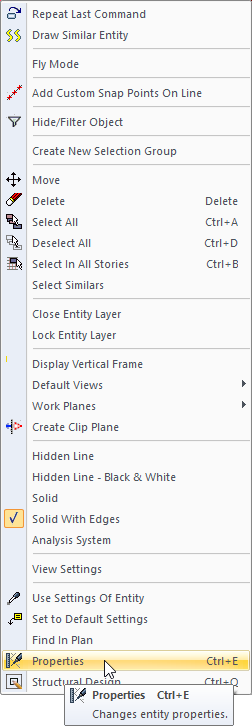

Location of the Single Angle Connection Settings Dialog

If the draw in fast mode is active, the connection settings will be opened automatically.

If the draw in fast mode is inactive, select the connection and click the right mouse button. Click the Properties line from the right click menu that opens.

Single Angle Connection Settings Dialog

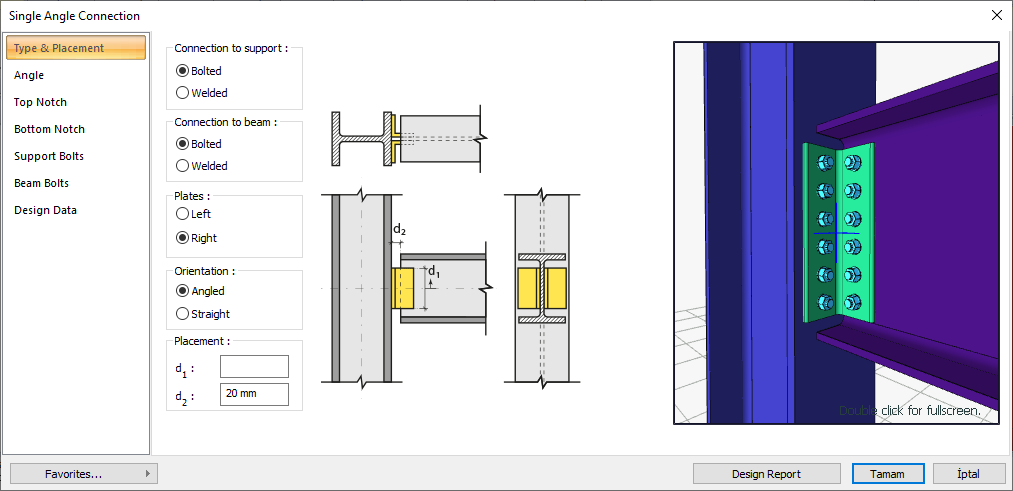

Type and Placement Tab

Specifications |

|---|

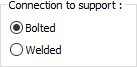

Connection to support  Bolted or welded connection types are selected for the support connection. |

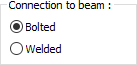

Connection to beam  Bolted or welded connection types are selected for the beam connection. |

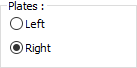

Plates  It is chosen whether the plate will be on the left or right of the beam body. |

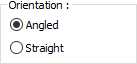

Orientation  One of the angled or straight options is chosen for the connection orientation. |

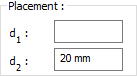

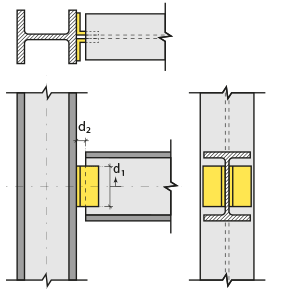

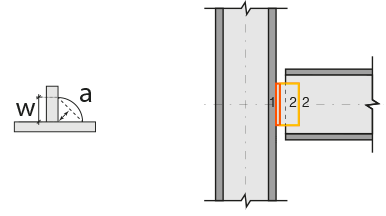

Placement  Placement values are entered. The values to be entered are shown in the schematic drawing. |

Schematic drawing  Connection and placement values are shown on the schematic drawing. |

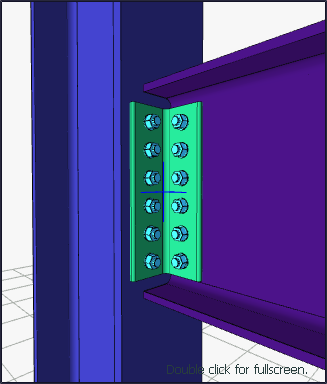

Preview  There is a preview of the connection. The selection made and the entered values can be followed simultaneously in the preview. |

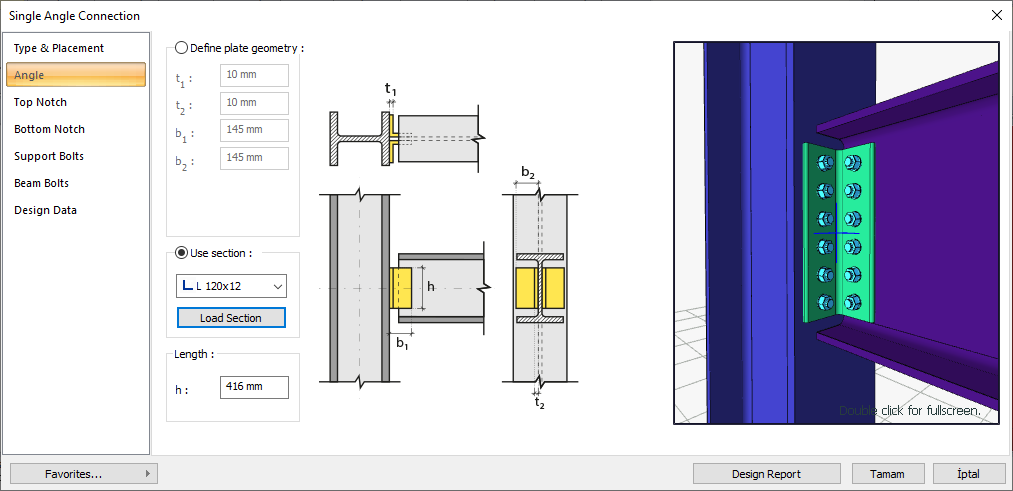

Angle Tab

Specifications |

|---|

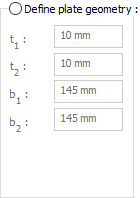

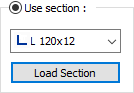

Define plate geometry  If the option is selected, it is determined by entering the angle values. The values to be entered are shown in the schematic drawing. |

Use section  By selecting the option, one of the ready-made L profiles is selected from the list as an angle bracket. By clicking on the load section button, you can reach the ready section library and reach the list of American and European finished rolling sections and select from the list. |

Length  Angle length value is entered. |

Schematic drawing  Connection and plate values are shown on the schematic drawing. |

Preview  There is a preview of the connection. The selection made and the entered values can be followed simultaneously in the preview. |

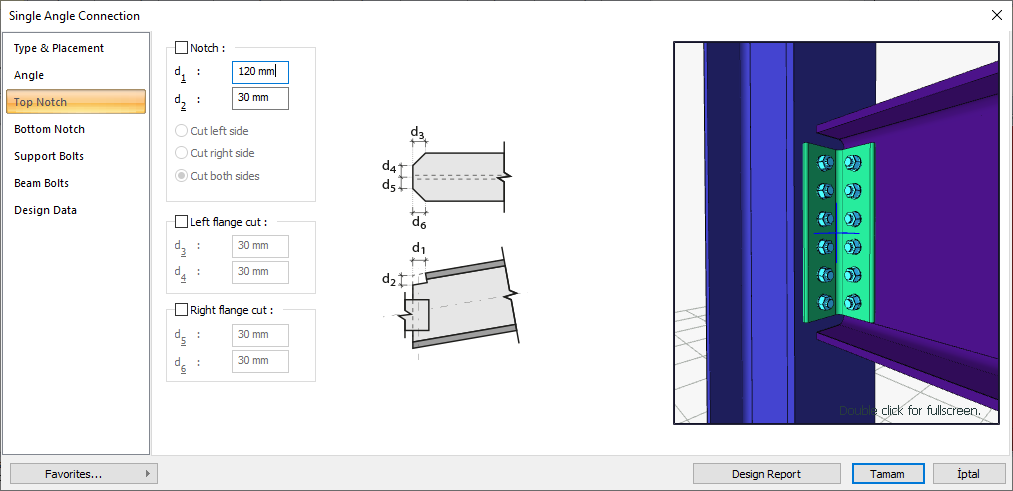

Top Notch Tab

Specifications |

|---|

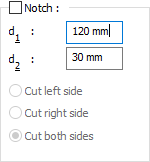

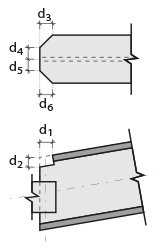

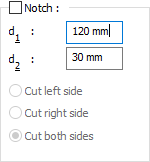

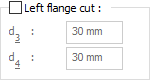

Notch  If the option is selected, notching is done according to the entered values. The values to be entered are shown in the schematic drawing. |

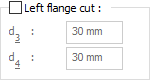

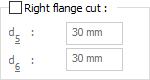

Left flange cut  If the option is selected, left flange cutting is made according to the entered values. The values to be entered are shown in the schematic drawing. |

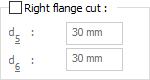

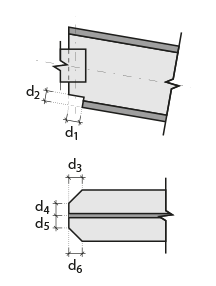

Right flange cut  If the option is selected, right flange cutting is made according to the entered values. The values to be entered are shown in the schematic drawing. |

Schematic drawing  Connection, notching and cutting values are shown on the schematic drawing. |

Preview  There is a preview of the connection. The selection made and the entered values can be followed simultaneously in the preview. |

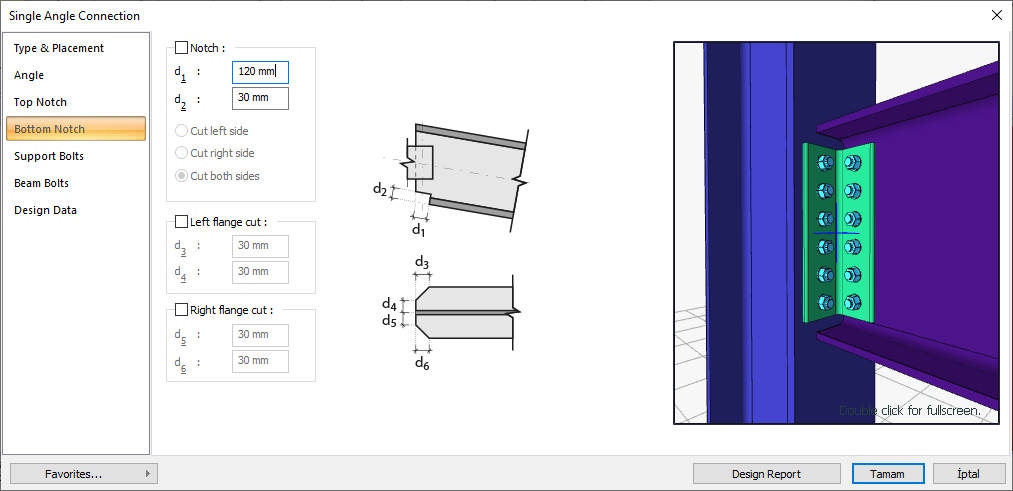

Bottom Notch Tab

Specifications |

|---|

Notch  If the option is selected, notching is done according to the entered values. The values to be entered are shown in the schematic drawing. |

Left flange cut  If the option is selected, left flange cutting is made according to the entered values. The values to be entered are shown in the schematic drawing. |

Right flange cut  If the option is selected, right flange cutting is made according to the entered values. The values to be entered are shown in the schematic drawing. |

Schematic drawing  Connection, notching and cutting values are shown on the schematic drawing. |

Preview  There is a preview of the connection. The selection made and the entered values can be followed simultaneously in the preview. |

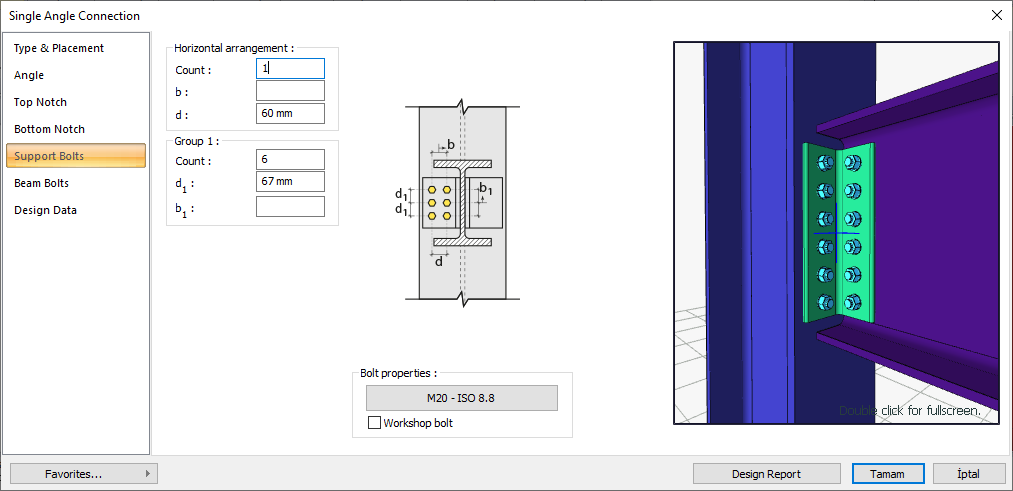

Support Bolts Tab

Specifications |

|---|

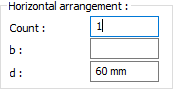

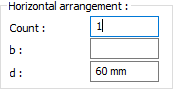

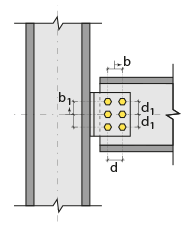

Horizontal arrangement  Horizontal arrangement settings (number of horizontal bolt columns, distance values ..) of support bolts are entered. The values to be entered are shown in the schematic drawing. |

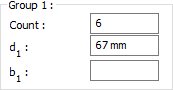

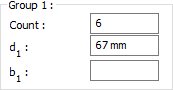

Group 1  Support bolts settings (number of lines, distance values ..) are entered. The values to be entered are shown in the schematic drawing. |

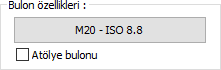

Bolt properties  The Hole and Bolt Parameters dialog is opened by clicking on the bolt properties button. The bolt properties are set in this dialog. |

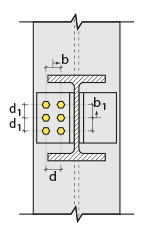

Schematic drawing  Connection and bolt placement values are shown on the schematic drawing. |

Preview  There is a preview of the connection. The selection made and the entered values can be followed simultaneously in the preview. |

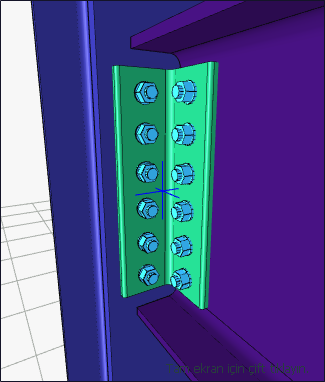

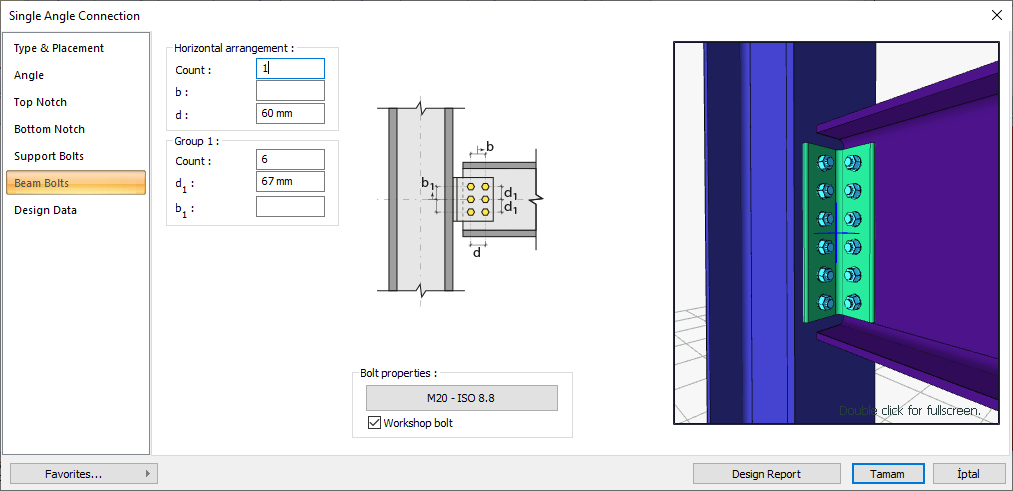

Beam Bolts Tab

Specifications |

|---|

Horizontal arrangement  Horizontal arrangement settings (number of horizontal bolt columns, distance values ..) of beam bolts are entered. The values to be entered are shown in the schematic drawing. |

Group 1  Beam bolts settings (number of lines, distance values ..) are entered. The values to be entered are shown in the schematic drawing. |

Bolt properties  The Hole and Bolt Parameters dialog is opened by clicking on the Bolt properties button . The bolt properties are set in this dialog. |

Schematic drawing  Connection and bolt placement values are shown on the schematic drawing. |

Preview  There is a preview of the combination. The selection made and the entered values can be followed simultaneously in the preview. |

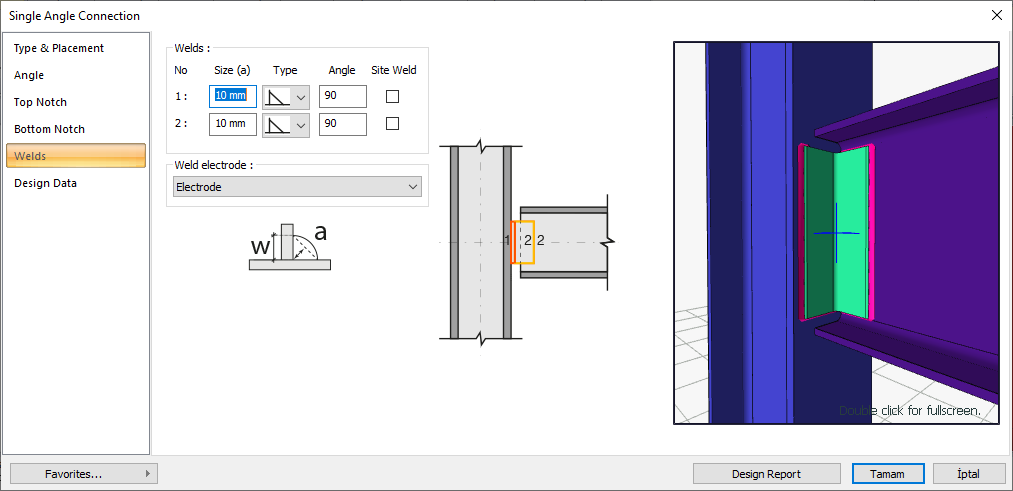

Weldings Tab

Specifications |

|---|

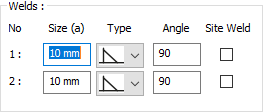

Welds  The thickness, type and angle values of the welds to be made at the connections are given. The information on whether it will be done on the construction site or not is entered. |

Weld electrode  The strengths of the welding electrodes are defined in the design inputs. The strength of the main element in the weld joint is controlled under the condition that it has less strength than the weld strength. If necessary, click the list and define "Create New…". To create the welding electrode, give the information "Name" and "Weld metal tensile strength" in the dialog that opens after clicking "Create New". Welding geometry is determined automatically by the program. These properties can be changed to easily determine the connection properties. Geometry features are in accordance with industry standards and in the form specified in AISC. Welding geometry is determined automatically by the program. These properties can be changed to easily determine the connection properties. Geometry features are in accordance with industry standards and in the form specified in AISC. |

Schematic drawing  Connection and source values are shown on the schematic drawing. |

Preview  There is a preview of the connection. The selection made and the entered values can be followed simultaneously in the preview. |

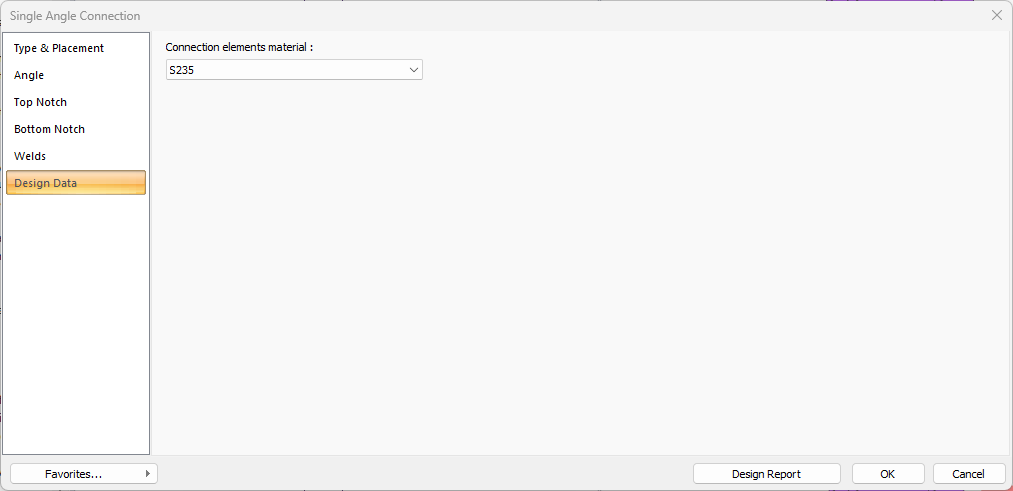

Design Data Tab

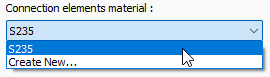

In the design data, the connection elements material is defined. The condition that the main element in the weld joint has less strength than the weld strength is controlled.

If necessary, click the list and define "Create New…". To create the connection elements material, give the information material definitions and values in the dialog that opens after clicking "Create New".

Next Topic