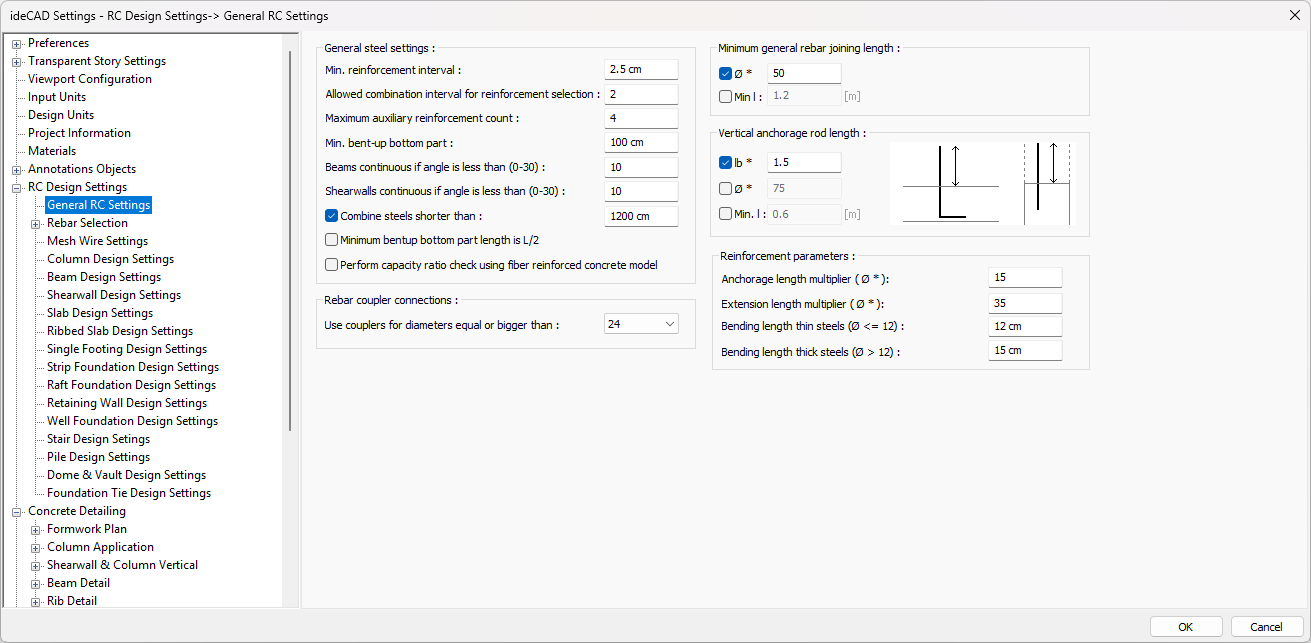

General RC Settings Section

With the General RC Settings, the design parameters in all concrete elements are determined. Minimum reinforcement interval, number of auxiliary reinforcement, general rebar joining length, anchorage rod length, capacity ratio check using fiber reinforced concrete model setting are made in the general concrete reinforcement settings window.

Specifications |

|---|

Min. reinforcement interval  It is one of the parameters that determines how the rebar diameters that can be defined in the rebar selection screen will be used during the placement of the rebar. Placement of rebar spaced smaller than the value written here is not made. Unless this condition is fulfilled, the diameter of the rebar is increased according to the rebar diameters marked in the rig selection parameters. |

Allowed combination interval for reinforcement  It is the value that determines the difference between the diameters to be used during the selection of rebar. For example, the diameters of 12, 14, 16 and 18 are marked in the selection of rebar for the straight and pleated rebar of the beam. If it is written 2 in this row, it means that the flat and pleat diameters could be 12 and 16 (or 14 and 18). |

Maximum auxillary reinforcemen count  It is the line that determines the maximum limit for additions in beam. The diameter is increased when the value written in this line is exceeded during reinforced concrete. In order to increase the diameter, the diameter values that can be used in the selection of the rebar must be selected in sufficient size. In the last diameter, the program places as many additions as possible. |

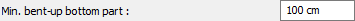

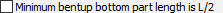

Min. bent-up bottom part   In beam, strip, rib, cassette beam openings, it is the value that determines whether the pile is broken or not. Beams break the moment at the zero point to the pillar. If the bottom part after breaking is smaller than the value written in this line, it will not break into the battery. This requirement applies if the "Minimum bentup bottom part length is L/ " line is not checked. If the L / 2 line is marked, the value written in the bottom of the minimum piles is compared with the half of the beam length and whichever value is greater is used. |

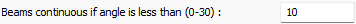

Beams continuous if angle is less than (0-30)  If the angle between the beams is smaller than the specified angle, these beams will be drawn as continuous beams. This value cannot be more than 30 degrees. |

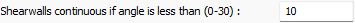

Shearwalls continuous if angle is less than (0-30)  If the angle between the shearwalls is smaller than the specified angle, these shearwalls will be drawn as continuous shearwalls. This value cannot be more than 30 degrees. |

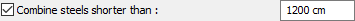

Combine steels shorter than  It is the parameter that determines how to cut straight, assembly and body reinforcements used in timed foundation expansions. If this option is not selected, the rebars are cut at each support regardless of the number and diameter of the rebars. If the option is selected, bars with the same number and diameter are combined for the value entered in this line. The reinforcement is cut at the nearest support before it reaches the written value. For example, consider a four-span strip foundation system. The spans are respectively - 4 m - 3.5m - 4 m - 5 m - and the assembly rebars are 2 pieces of 12 rebar for each beam. The maximum length of the rebar is given as 12 m in this line. If the option is selected, the rebar will be extended up to the 3rd support (since it is 11.5 m <12 m in total), it will be cut at the 3rd support, and a new assembly rebar will be laid on the fourth beam. If the line is not marked, one rebar will be laid for each beam regardless of the length of the rebar. |

Perform capacity ratio check using fiber reinforced concrete model  When this option is checked, the three-dimensional capacity curve of the reinforced concrete element (column-beam-wall) is calculated using the section fiber model and the capacity ratio of the reinforced concrete element is controlled. |

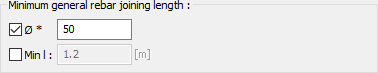

Minimum general rebar joining length  These are the options that determine the minimum joining length of the reinforcement. Ø*: According to the given multiplier value, overlap length will be determined according to the multiple of the reinforcement diameter. Min. l: Overlap length will be determined according to the given minimum length value. If both options are not checked, the overlap length is taken as Lb calculated according to TS500 . |

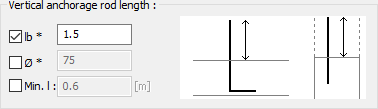

Vertical anchorage rod length  It is the option that determines the minimum length of column/shearwall sprouts. The condition for the relevant options will be applied to the foundation, column and shearwall sprouts. Lb *: According to the given multiplier, the length will be determined by the multiple of Lb. Lb is the clamping length described by the formula in TS500. Ø*: According to the given multiplier, the length will be determined according to the multiple of the rebar diameter. Min. l: The anchorage length will be determined according to the minimum length value given. |

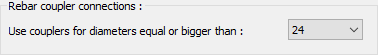

Use couplers for diameters equal or bigger than  The smallest diameter of rebar to be manufactured with sleeve rebar attachment is selected from the list here. |

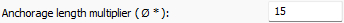

Anchorage length multiplier  It is the value that determines the length of the anchor rebar in the strengthening drawings. The entered value is used by multiplying the diameter of the rebar. |

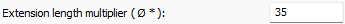

Extension length multiplier  It is the value determining the length of the anchor rebars drawn from the wall to the upper story in the strengthening drawings. The entered value is used by multiplying the diameter of the rebar. |

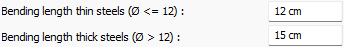

Bending length thin/thick steels  It is the value that determines the miter lengths of the rebars. The entered value is used by multiplying the diameter of the rebar. |

Next Topic