Steel Column Design per AISC 360-16

Steel Column Design according to AISC 360-16 is explained in detail under this title.

Definitions

Steel columns are designed under compression, tension, or combined effect depending on the loading conditions.

After the analysis, appropriate controls are made and reported according to the internal force situation.

Design Members for Compression

There are 2 main types of buckling, local and global buckling, in the elements under compressive force.

Local Buckling

Local buckling occurs when some part or parts of the cross-section of a column are slender that they buckle locally in compression.

Limit values for the classification of cross-sections for the local buckling boundary condition are given in AISC 360-16 B.4 and Table B4.1a for cross-sections under compressive force.

Global Buckling

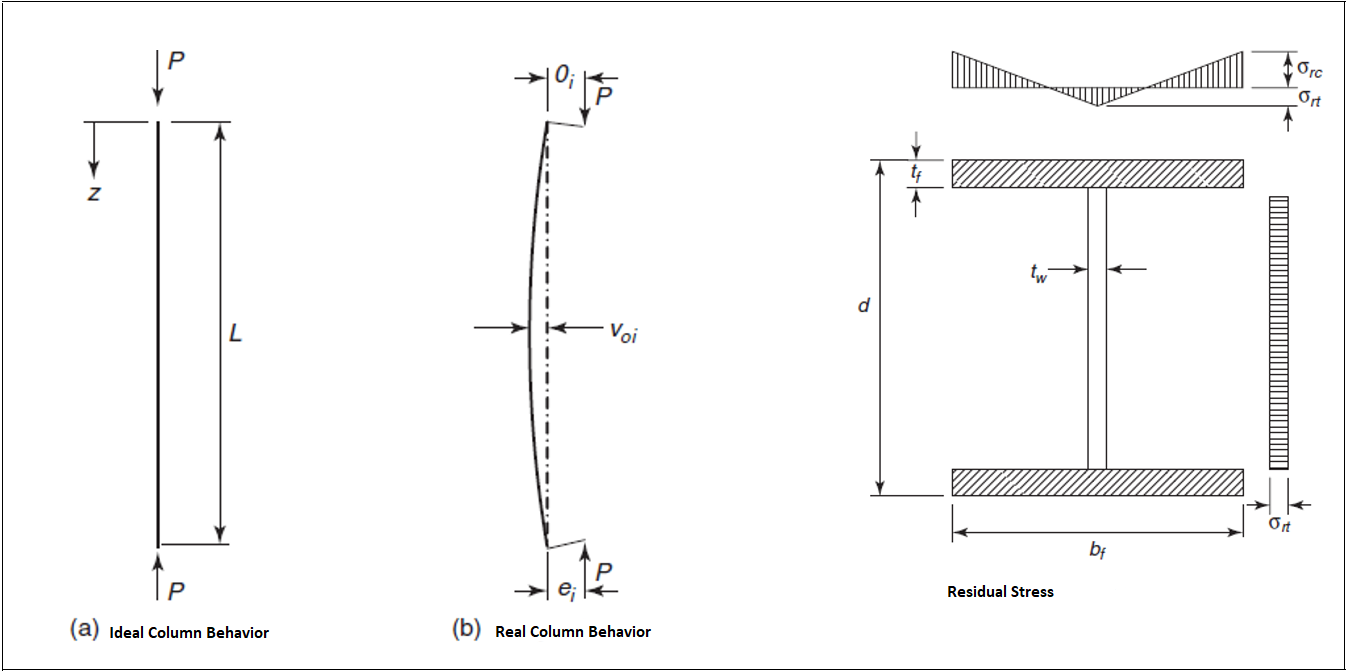

Elements under the effect of compression may not function as an ideal compression element due to various reasons, although the flexure moment does not occur as a result of loads. The most important reasons are:

Initial Curvature

Load eccentricity

Residual Stresses

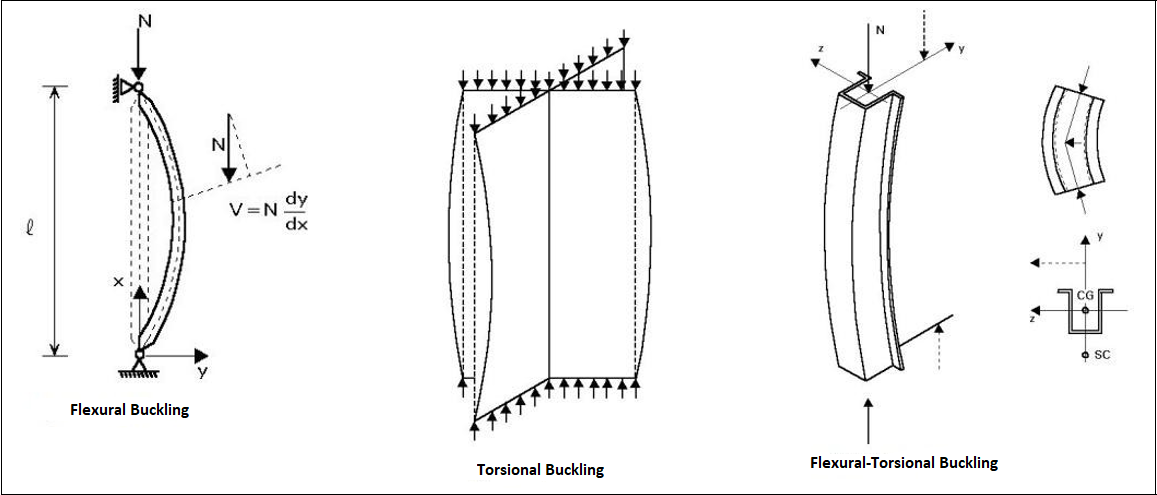

Global buckling is divided into 3 categories: Flexural buckling, Torsional buckling, and Flexural-Torsional buckling.

Flexural Buckling Limit State

The buckling deformations all lie in one of the principal planes of the column cross-section. No twisting of the cross-section occurs for flexural buckling.

The limit state of flexural buckling is applicable for axially loaded columns with doubly symmetric sections, such as bars, HSS, and round HSS, and I-shapes and singly symmetric sections, such as T- and U-shapes. Flexural buckling is the simplest type of buckling.

Flexural Buckling Design with AISC 360-16

The compressive strength of the elements is determined according to the axial force acting from the section center of gravity. According to the regulation, the flexural buckling limit state is considered in all compression elements, regardless of cross-section properties.

First of all, local buckling control should be done. The calculation is made to determine whether the elements are compact or non-compact.

Torsional Buckling Limit State

Buckling occurs when the element rotates around its longitudinal axis. The limit state of torsional buckling applies to axially loaded columns with doubly symmetric open sections with very slender cross-sectional elements consisting of 4 corners placed back to back.

Torsional Buckling Design with AISC 360-16

The compressive strength of the elements is determined according to the axial force acting from the section center of gravity.

In the torsional buckling boundary case where buckling occurs by the rotation of the element around its longitudinal axis (+ shaped cross-section or open cross-section elements consisting of 4 corners placed back to back), the elastic buckling stress Fe is calculated for doubly symmetric members by Equation E4.2.

Flexural - Torsional Buckling Limit State

The buckling deformations consist of a combination of twisting and bending about two flexural axes of the member.

The symmetry axis is the y-axis, where the buckling around the y-axis is caused by the tilting and rotation of the element around its longitudinal axis. The limit state of flexural-torsional buckling applies to columns with singly symmetric shapes, such as double angle, T- and U-shapes, and asymmetric cross-sections.

Flexural-Torsional Buckling Design with AISC 360-16

The compressive strength of the elements is determined according to the axial force acting from the section center of gravity.

With the symmetry axis being the y-axis, the elastic buckling stress Fe in the flexural-torsional buckling limit state where buckling around the y-axis occurs by tilting and rotating around the longitudinal axis, Fe Equation E4-3 is calculated.